Feasibility - Your Ideas Consulting

Main menu

- Home

-

Product Development

- Development Overview

- by Phase Results:

- Proposal

- Feasibility

- Realization

- Validation

- Commercialization

-

Process Development

- Processes Overview

- by System Processes

- Requirements

- Product Risks

- Verification & Validation

- Product Configurations

- Consulting

- Training

-

About

- Mission

- Management

- Juergen Friedrichs

- Advisory Board

- Knut Bartl

- Alfred Lang

- Guenther Schatz

- Copyright

- Contact

Feasibility

Phase Feasibility

Compilation and consideration of the following deliverables is recommended during this phase:

Requirements need to be compiled comprehensively on a product/ system level e.g. by using a content template.

Critical contents to be considered:

-

-

-

-

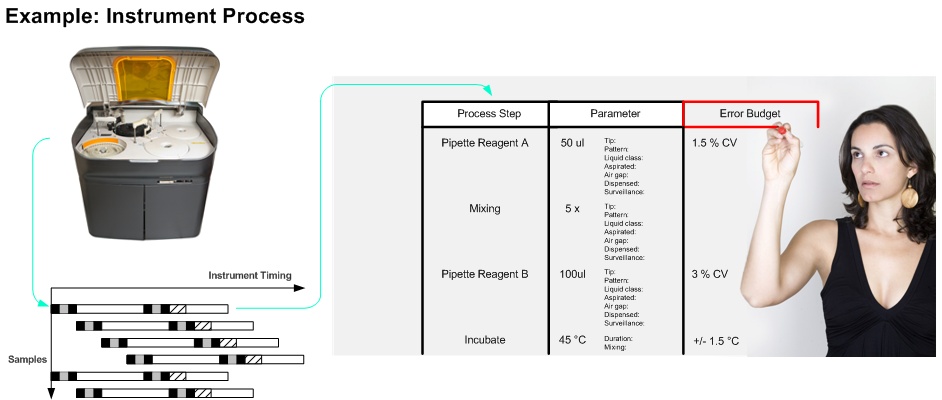

(e.g. reagent onboard time variation, pipetting variation, sample stability)

-

-

The requirements management plan defines the requirements process for a specific projects, including:

-

-

-

-

-

-

-

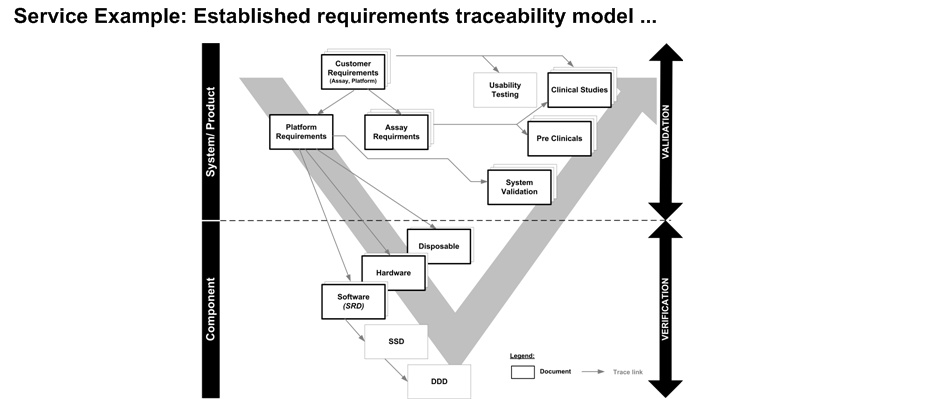

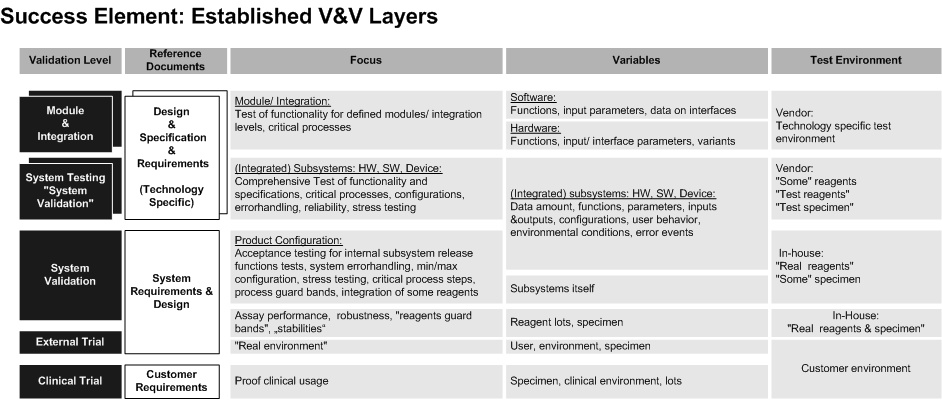

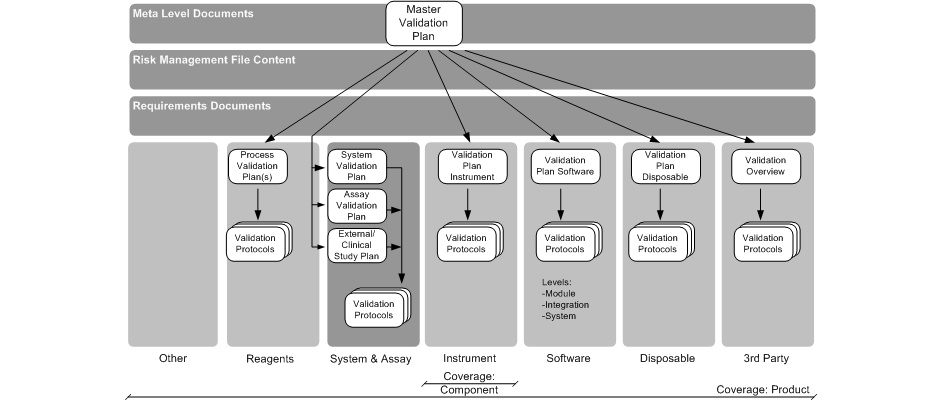

The Master Validation Plan provides a breakdown into all V&V activities (see layer model below) for a product (platform & assays) with its components, including manufacturing.

This planning process will result in a hierarchy of V&V plans (see below).

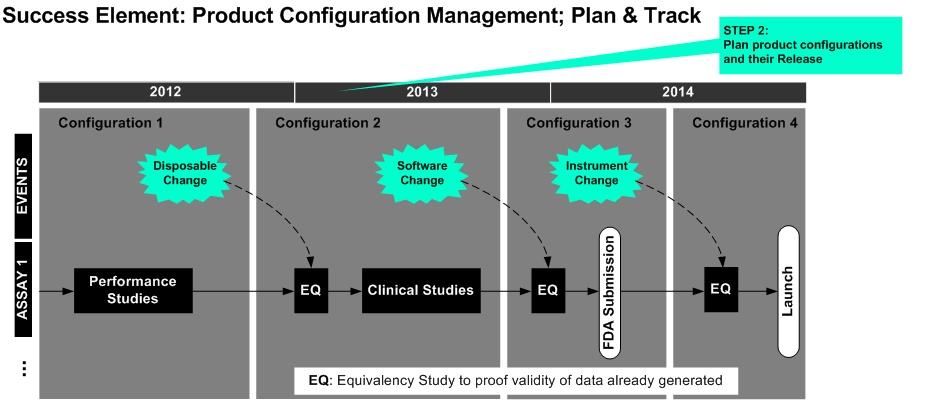

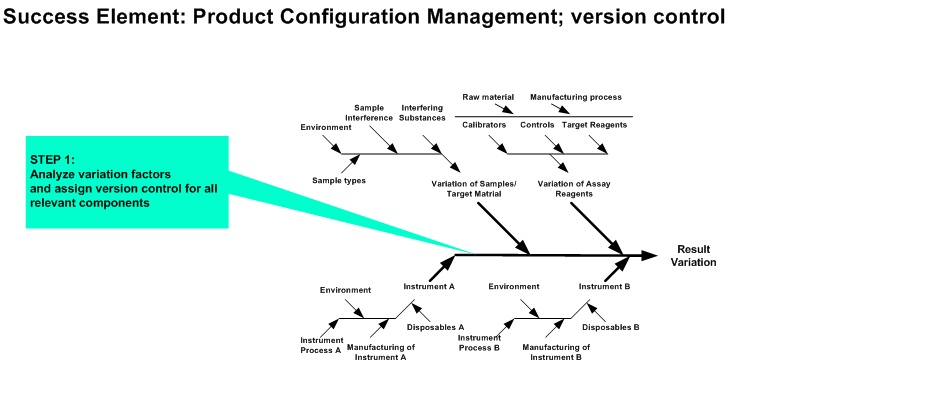

The Configuration Management Plan contains definitions and descriptions of product configuration scope and release along the lifecycle.

The interfacing of platform versions with reagent lots is provided . The document plans the introduction of upcoming changes (design changes, obsolescence ...) in configurations.